At Technical Glass Products, we take pride in advancing how glass materials enable high-performance solutions across demanding industrial applications. One area where quartz glass shines is in infrared (IR) heating systems—whether in manufacturing, scientific instrumentation, or specialized processing. In this post, we explore how quartz glass is uniquely suited to infrared heating, what makes it indispensable, and how our expertise ensures the solutions we offer fulfill the strict requirements of IR heating clients.

What Is Infrared Heating, and Why Quartz Glass?

Infrared heating refers to the emission of radiant energy in the infrared portion of the electromagnetic spectrum, which is absorbed by materials to produce heat. Unlike convective or conductive heat transfer, IR heating can directly target objects or surfaces, enabling fast, efficient heating. This method is widely used in processes like drying, curing coatings, sterilization, food processing, glass tempering, semiconductor fabrication, and more.

Quartz glass (also known as fused silica or fused quartz) plays a critical role in these systems because of properties that are essential to IR heating:

- High transmission in the infrared spectrum: Quartz allows a wide portion of infrared wavelengths to pass through with minimal absorption, enabling efficient transfer of radiant energy.

- Excellent thermal stability: Quartz can withstand very high temperatures without softening or deforming—critical when IR heaters are operating at high power.

- Low thermal expansion: This helps maintain optical clarity and dimensional stability during rapid temperature changes, reducing risks of thermal shock.

- Chemical purity and inertness: Quartz resists degradation from many environmental factors (oxidizing/reducing atmospheres, moisture, etc.), which increases lifespan and helps maintain consistent performance.

- Mechanical strength and optical quality: Good surface finish, scratch resistance, and uniformity are essential so that the IR radiation isn’t prematurely scattered, absorbed, or otherwise degraded.

Key Applications Where Quartz Glass Is Preferred

Several infrared heating applications benefit significantly from the use of quartz glass:

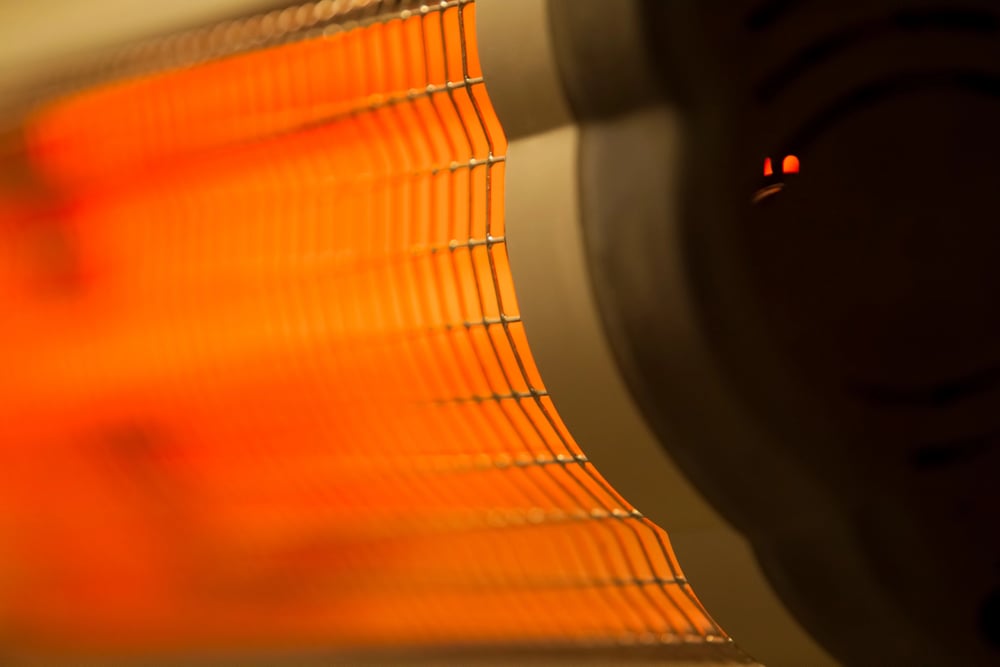

- Infrared Heaters & Lamps

IR heating elements are often enclosed behind quartz tubes or bulbs. The quartz envelope protects the filament or heating coil, while allowing IR output with minimal loss. For example, quartz tube lamps are standard for IR curing processes. - Drying and Curing of Coatings and Paints

In automotive and industrial paint shops, infrared lamps are used to cure paints, varnishes, or coatings quickly and uniformly. Quartz covers or panels help ensure the IR radiation is transmitted effectively to the coated surfaces. - Thermal Processing and Annealing

Semiconductor, glass, and optical component fabrication often require annealing or otherwise heating with precise temperature control. Quartz’s optical clarity, uniformity, and low absorption make it ideal for such environments. - Food Processing and Sterilization

Infrared heating is used to pasteurize or sterilize surfaces and certain foods. Quartz windows or shields protect the heating source, allowing high efficiency and hygiene. - Infrared Drying in Textile and Paper Industries

Quick moisture removal demands high IR throughput; quartz panels or tubes allow consistent energy delivery.

What Specifications Matter: What We at Technical Glass Products Focus On

When supplying quartz glass for IR heating systems, there are critical factors we at Technical Glass Products pay close attention to:

- Spectral transmission profile – ensuring that the quartz glass transmits specifically in the IR wavelengths required by the system (e.g. near-IR, mid-IR).

- Thickness and surface finish – thicker glass may attenuate certain bands; surface finish (polished vs ground) affects scattering and reflectance.

- Thermal shock resistance – handling rapid temperature ramping without cracking is essential.

- Purity and inclusions – defects, bubbles, or impurities can absorb heat, worsen performance, or lead to hot-spots.

- Dimensional tolerances and shape – tubes, rods, windows, shields must match exact specifications for fitting, mounting, or sealing.

- Coatings or treatments – sometimes anti-reflective coatings, or protective coatings, may be applied depending on the environment or usage.

Why Technical Glass Products Is a Leader in Quartz Glass for IR Heating

- Proven Manufacturing Expertise: Our experience in fabricating high-quality fused silica and quartz components ensures we meet stringent requirements for optical, thermal, and mechanical performance.

- Quality Control: We implement rigorous inspection protocols to ensure purity, geometric accuracy, and consistency.

- Custom Design Capability: Whether clients need standard quartz windows, custom-shaped tubes, or specialized shields, we work closely to design the component that integrates seamlessly with their IR heating system.

- Support Through Material Selection: We assist clients in selecting the right grade of quartz, determining appropriate thickness, finish, and any needed post-processing treatments to optimize performance and longevity.

- Durability & Reliability: Our components are designed to perform over extended operational periods, resisting degradation even under intense thermal cycling. This reduces downtime and maintenance costs.

Considerations & Best Practices to Maximize IR Heating Performance

To ensure the quartz glass component contributes its full potential, some best practices should be followed:

- Match the quartz grade to the wavelength required: Near IR, mid-IR, far IR all have different absorption or scattering behavior in quartz.

- Allow for proper mounting and accommodation of thermal expansion to avoid stress fractures.

- Keep surfaces clean — dust, spatter, coatings or oxidation on quartz surfaces can drastically reduce transmission and lead to inefficiency or overheating.

- Ensure adequate cooling or airflow where needed, especially for elements in close proximity to sources of heat.

- Periodic inspection to detect any cracks, chips, or inclusion growth that may affect performance or safety.

Looking Ahead: Innovations & Emerging Uses

Quartz glass continues to be part of innovation in infrared heating:

- Advanced coatings that can improve transmission or reflect unwanted wavelengths, increasing efficiency.

- Integration with fiber optics or advanced IR guiding systems for more precise heat delivery.

- Manufacturing with ultra-low defect densities or novel quartz composites for higher durability.

- Applications in renewable energy systems, such as solar thermal collectors, where quartz glass plays a key role in high-temperature transmissive windows.

Conclusion

Infrared heating applications demand materials that can deliver performance under high temperature, rapid cycling, and exacting optical requirements. Quartz glass delivers on all fronts: high IR transmission, thermal stability, purity, and precision. At Technical Glass Products, we are committed to supplying quartz components that meet—and exceed—the demands of IR heating systems, helping our customers attain greater efficiency, reliability, and long-term value.

If your next project involves infrared heating and you need quartz glass solutions—whether standard or custom—contact us.